Sold and supported by Disruptive Mining Technologies

For Sales and Technical Enquiries: Steven Amor 0407 699 416 steve@disruptivemining.tech

1. Product Overview

Product Name: Dengus Group Remote Tyre Deflation System for Loaders, Haul Trucks, Watercarts and all tyred HME.

Model: RDU1

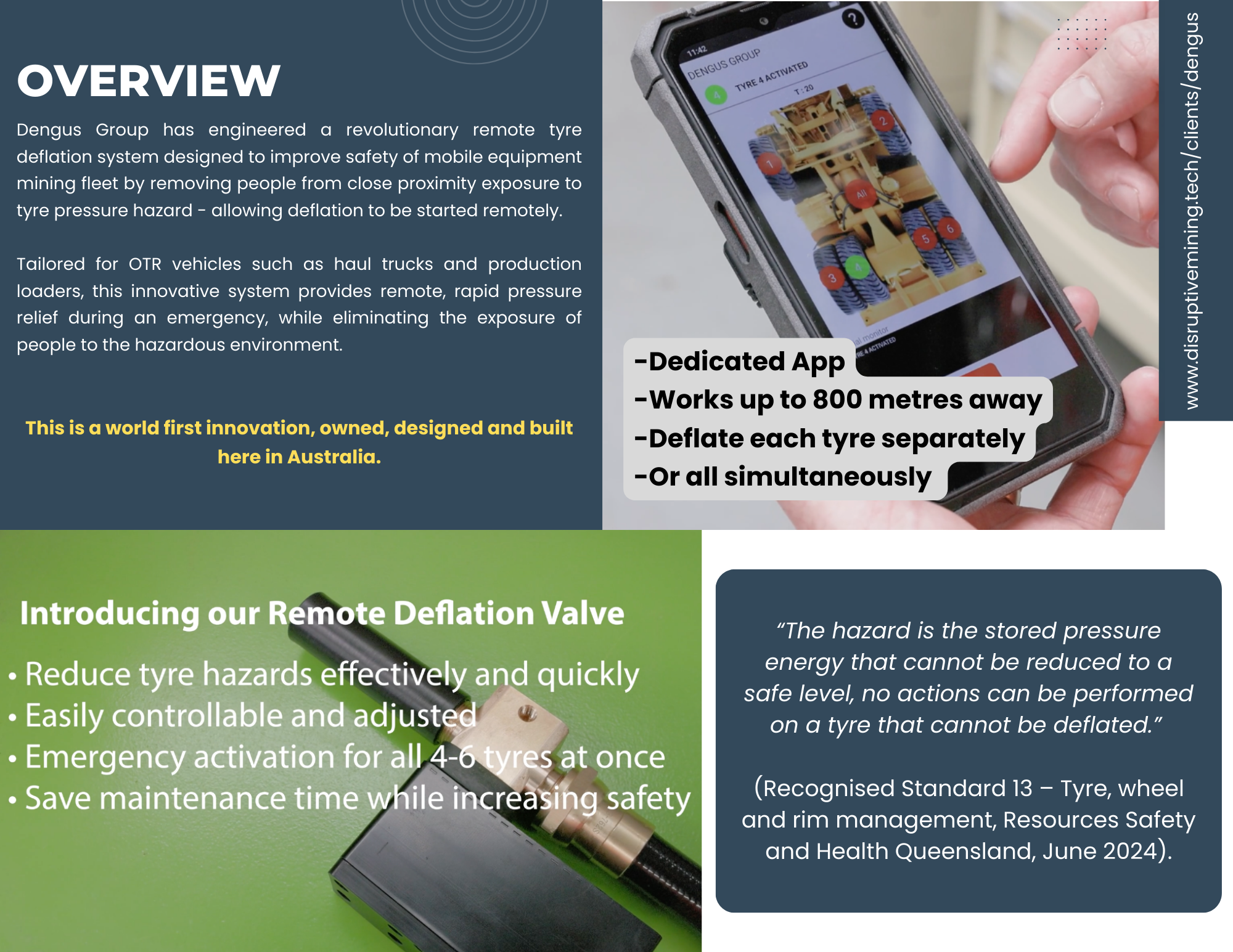

Description: A revolutionary remote tyre deflation system, purpose-built to improve safety for mining fleets by eliminating the need for personnel to work in close proximity to hazardous tyre pressure. Designed and built in Australia, this world-first innovation empowers operators to initiate tyre deflation remotely, addressing significant safety risks associated with manual tyre handling in mining environments.

Applications:

Off-the-road (OTR) equipment, including haul trucks, watercarts and production loaders (proven on CAT785 / CAT994 class and above).

Emergency tyre pressure relief during critical events

Routine deflation to ensure safe tyre handling prior to workshop servicing

Key Features and Benefits

Remote Activation from a Safe Distance: With an operational range of up to 800 metres, the system enables immediate deflation initiation.

Safety: By removing workers from high-risk areas exposed to tyre pressure hazards, the system dramatically reduces the potential for fatal accidents and serious injuries, addressing a long-standing safety challenge in the mining industry.

Operational Efficiency: The integrated hardware and software package minimizes tyre workshop downtime. It allows tyre fitters to remotely control deflation processes, thereby freeing them to multitask and improve overall maintenance workflow.

Choice of deflation methods: Tyres can be deflated individually, or all tyres on a vehicle can be simultaneously activated in an emergency situation.

Proven Global Success: Deployed across surface mining operations in Australia and overseas, this innovation has demonstrated significant safety and efficiency improvements in real-world environments.

Unique, Locally Developed Solution: Owned, designed, and built in Australia, this system is the only true remote deflation capability on the market—a solution born out of the firsthand experience.

High Compatibility: Proven compatible with common tyre valve hardware, chains, liquid additives and TPMS / monitoring systems.

For Coal Mines located in Queensland, Australia this system has been designed with Recognised Standard 13 – Tyre, Wheel, and Rim Management (Resources Safety and Health Queensland, June 2024) in mind, particularly section 4.6 Operations and Hazardous Conditions Management – to allow tyre pressure deflation to occur whilst tyre is in hazardous condition that would generally require equipment park up.

2. What’s in the box?

o Hand-held Controller: (Part No. HHU) Portable unit for deflation activation. A minimum of ONE (1) unit is required at each site in order to activate the remote deflation - additional controllers can be purchased for additional flexibility or as spares.

o Deflation Valves: (Part No. RDD-01) Individually mounted (one per wheel) to allow selective or simultaneous activation.

o Rock Valve Guard: [Option] (Part No RVG-01) Provides additional protection against rock damage.

3. Compatibility

· Tyre Hardware:

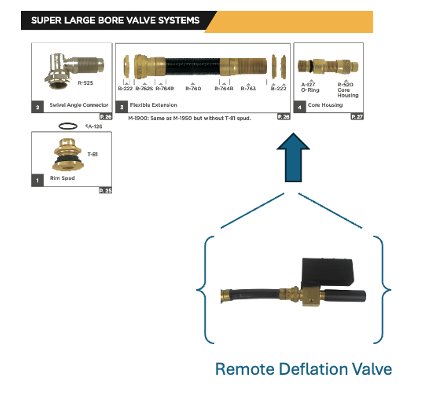

o Designed for Super Large bore valve systems, but compatible with the most common mining tyre valve standards using adapters: large bore and mega bore (mega-bore version expected late 2025).

o Fits most existing rim valve mounting points, where used.

· Field-proven compatible with:

o Tyre chains

o Air or nitrogen filled

o Liquid tyre additives

o TPMS / Monitoring systems including RIMEX Tyresense, Michelin MEMS and Bridgestone Itrack.

· System / Network Requirements:

o Will not interfere with existing site communication networks, such as wifi and autonomous haulage fleet systems (Has been proven on mine sites working alongside EPIROC and CAT autonomous fleets with zero interference)

o Each hand-held controller can control up to 255 units (after this, additional controllers are required).

4. Installation

Installation Requirements:

Typical installation labour: approx. 2 hours per machine.

Fig 1 – Typical installations using existing rim mounting point or optional rock valve guard for deflation valve mounting.

Remote Deflation Valve Part No. RVG-01 is labelled as “L3”

Fig 2 – The Remote Deflation Valve within a typical Super Large Bore Valve System.

5. Maintenance Instructions

Suggested maintenance interval:

Daily:

operator visual inspection: no obstructions or noticeable damage.

· Monthly or with scheduled service:

o Activation of each valve open/close from hand-held unit.

o Visual inspection of deflation valves, hoses and rock guard to confirm no obstructions or noticeable damage.

· 18 months:

(optional) Service Exchange (brass valve body, o-rings and seals replaced).

Note, there are no user-maintainable parts, complete unit to be returned to supplier for service exchange and/or repair.

6. Warranty, Support, & Additional Accessories

Warranty:

Coverage: 12 months parts (return to supplier).

Technical Support:

24/7 technical support via Phone/Email/Website.

Onsite support options available as required (additional fee).

7. Technical Specifications

Sold and supported by Disruptive Mining Technologies

For Sales and Technical Enquiries: Steven Amor 0407 699 416 steve@disruptivemining.tech